Industrial Design for IoT: Balancing Aesthetics and Engineering

We transform complex technology into market-ready products, creating enclosures that protect your electronics while ensuring ergonomics, durability, and a premium user experience.

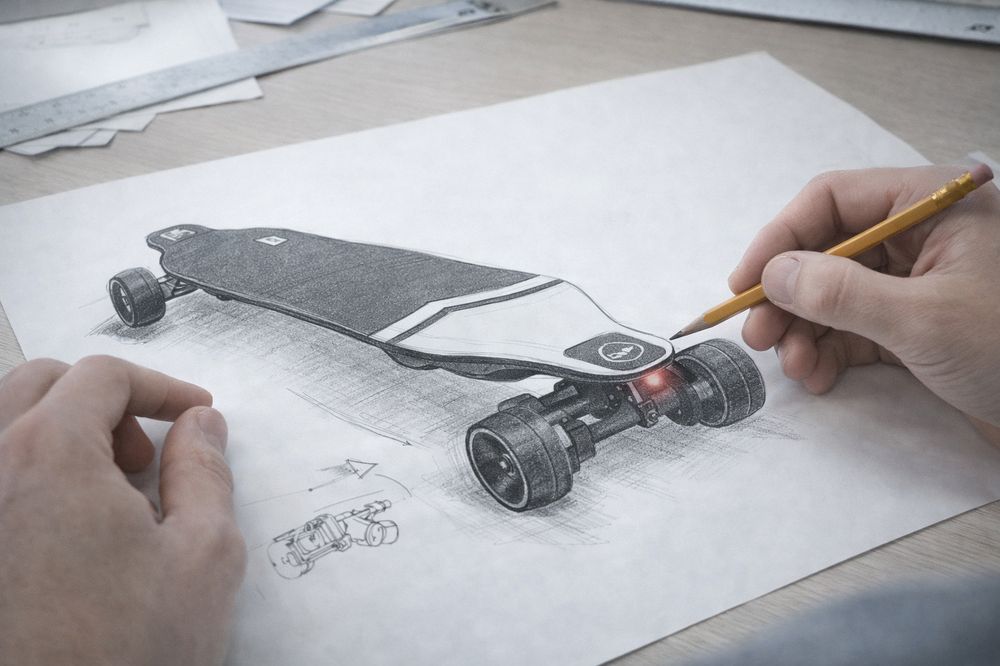

Concept & Aesthetics

We define the look and feel of your device, ensuring it aligns with your brand identity while maintaining a focus on user-centric ergonomics.

Mechanical Engineering

High-precision 3D modeling and structural analysis to ensure perfect fitment of internal components and long-term mechanical reliability.

Design for Manufacturing (DFM)

We optimize every part for mass production—focusing on injection molding, CNC, or die-casting—to minimize costs and assembly complexity.

Capabilities

Materials & Processes:

Expertise in plastic injection molding, metal stamping, die-casting, and advanced surfacing for high-quality finishes.

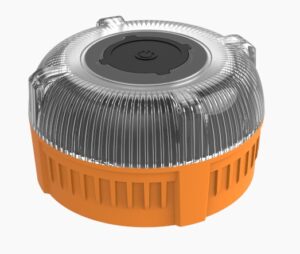

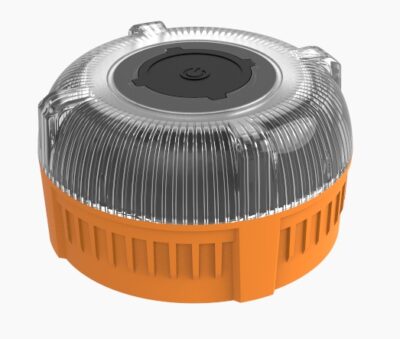

Environmental Protection:

Design for Ingress Protection (IP65, IP67, IP68) and impact resistance (IK ratings) to ensure reliability in harsh or outdoor environments.

Thermal Management:

Advanced thermal simulation and design of passive cooling solutions, including integrated heat sinks and optimized airflow.

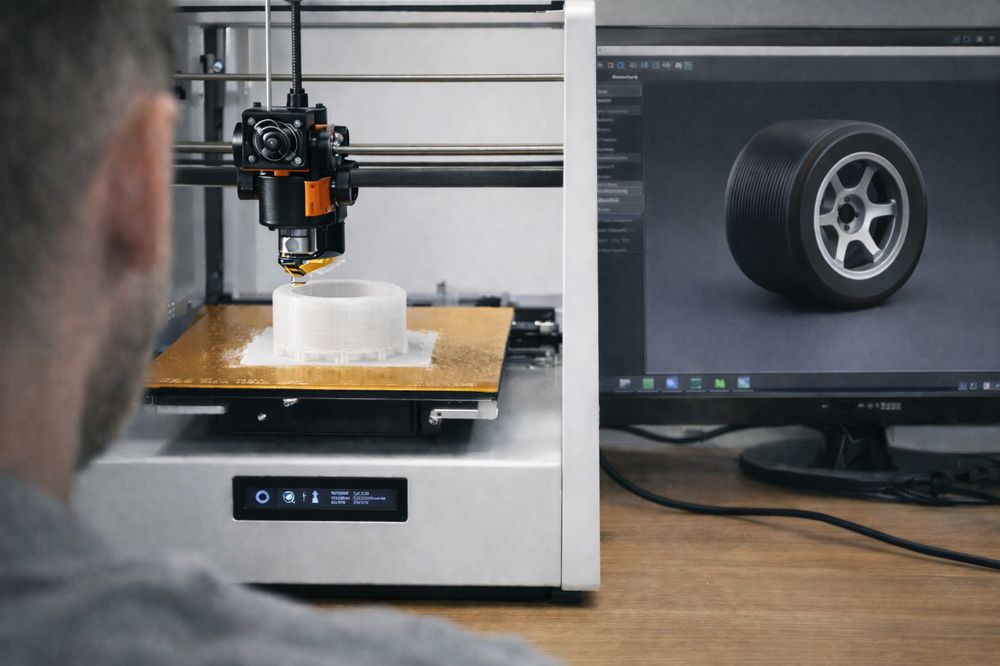

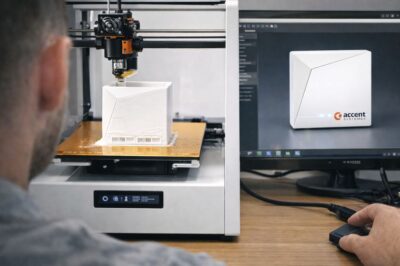

Rapid Prototyping:

High-fidelity prototypes using SLA/SLS 3D printing and CNC machining for functional testing and form validation before tooling.

Certification & Testing:

Pre-compliance testing for UV resistance, chemical compatibility, and mechanical stress to meet international standards.

Tell Us Your Project!

Testimonials

Boehringer Ingelheim

“Great company to work with. Both very competent and very creative people and just good guys to work with. We enjoyed it very much!”

Martiderm

“They have always been very receptive and eager to help us in anything that they

could. Thanks to Accent Systems we really succeeded”

DDB

“What really makes the difference is the willingness to do whatever’s necessary so that the product becomes a reality.”

Triomf Systems

“El proceso de desarrollo con Accent Systems fue muy rápido y es que en cuestión de tres meses ya disponíamos de un prototipo funcional”