Industrial-Scale IoT EMS Manufacturing and PCB Assembly

We provide end-to-end IoT EMS manufacturing services, bridging the gap between design and mass production. From small batches to high-volume runs, we ensure your IoT hardware is built to the highest quality standards with optimized supply chain management.

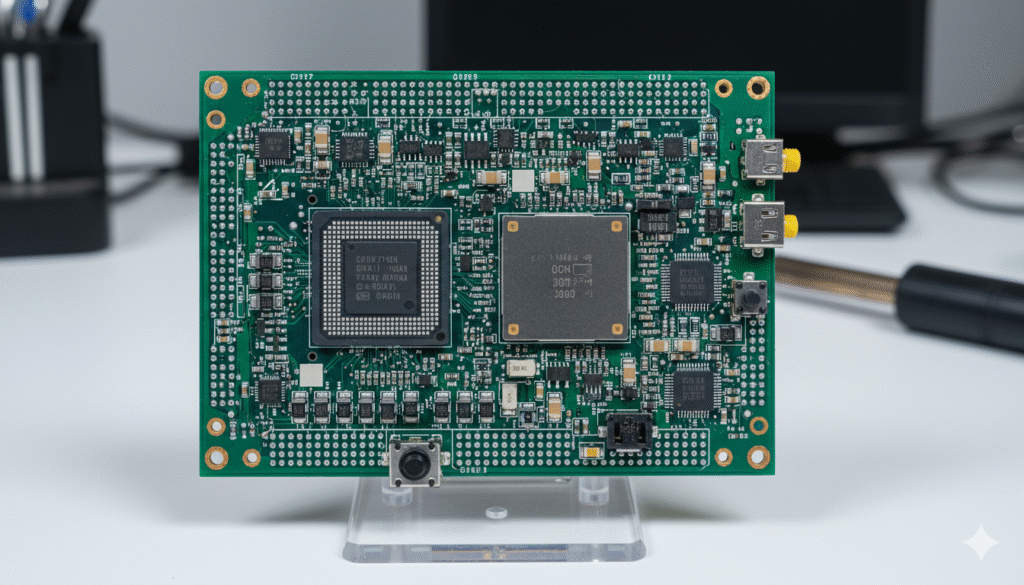

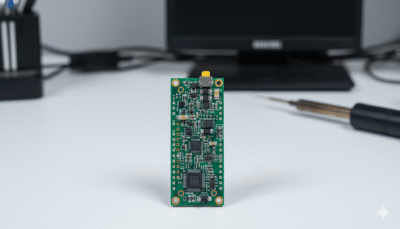

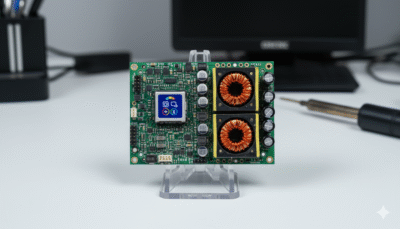

Advanced PCBA Assembly

State-of-the-art SMT and through-hole (THT) lines specialized in high-precision and high-density boards for complex IoT EMS manufacturing.

Flexible Production Volumes

Our facilities are optimized to handle everything from initial pilot runs and NPI (New Product Introduction) to large-scale industrial production.

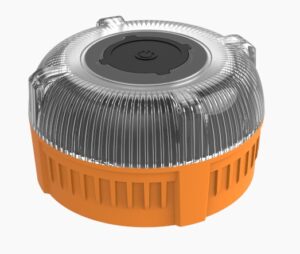

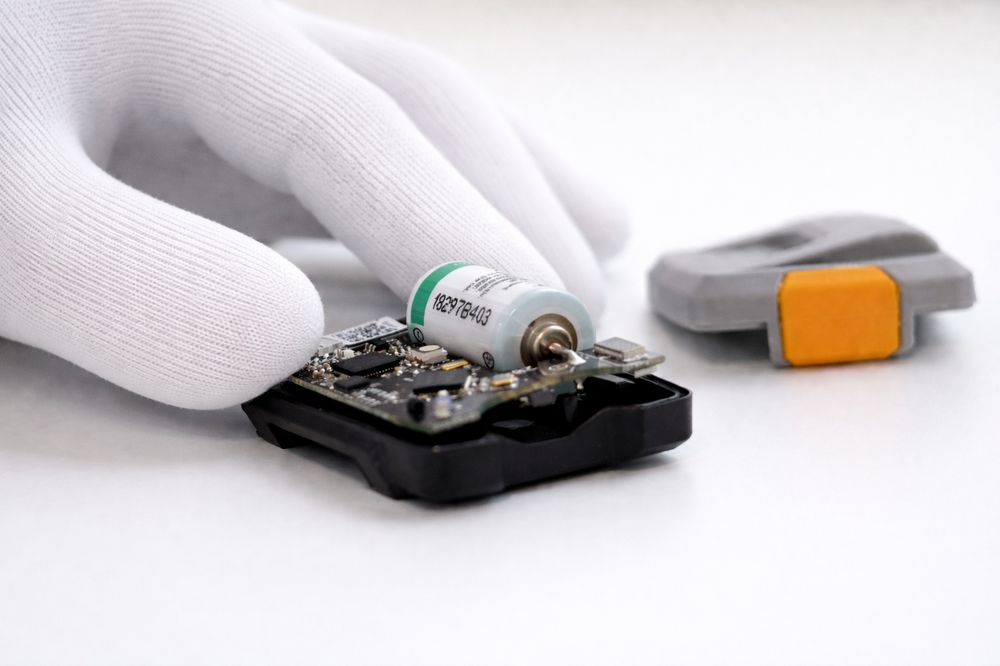

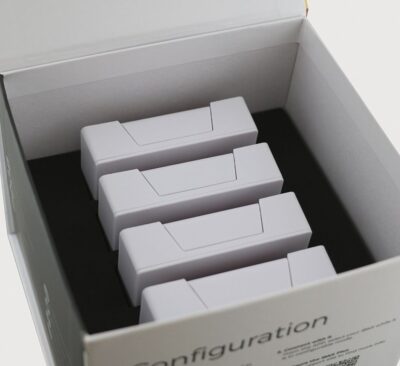

Turnkey Box Build

Complete product assembly services, including enclosure integration, final functional testing, custom labeling, and retail-ready packaging.

Capabilities

Assembly Technologies:

High-speed SMT lines, fine-pitch component placement (BGA, QFN, 01005), and lead-free wave soldering for robust IoT EMS manufacturing.

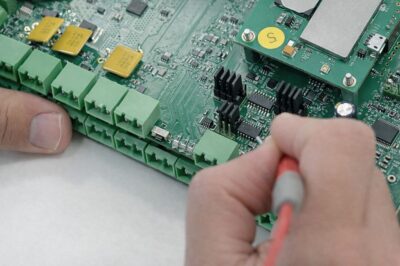

Quality Control:

Automated Optical Inspection (AOI), X-ray inspection for hidden solder joints, and In-Circuit Testing (ICT) to ensure 100% functional yield.

Supply Chain Management:

Global component sourcing, buffer stock management, and obsolescence monitoring to mitigate risks in the IoT EMS manufacturing process.

Custom Testing Jigs:

Design and development of bespoke functional testing fixtures and software to automate quality validation on the production line.

Logistics & Fulfillment:

Global shipping and distribution management, ensuring your finished IoT products reach their destination securely and on time.

Tell Us Your Project!

Testimonials

Boehringer Ingelheim

“Great company to work with. Both very competent and very creative people and just good guys to work with. We enjoyed it very much!”

Martiderm

“They have always been very receptive and eager to help us in anything that they

could. Thanks to Accent Systems we really succeeded”

DDB

“What really makes the difference is the willingness to do whatever’s necessary so that the product becomes a reality.”

Triomf Systems

“El proceso de desarrollo con Accent Systems fue muy rápido y es que en cuestión de tres meses ya disponíamos de un prototipo funcional”